NanoPlasmonic Sensing will change things for the better

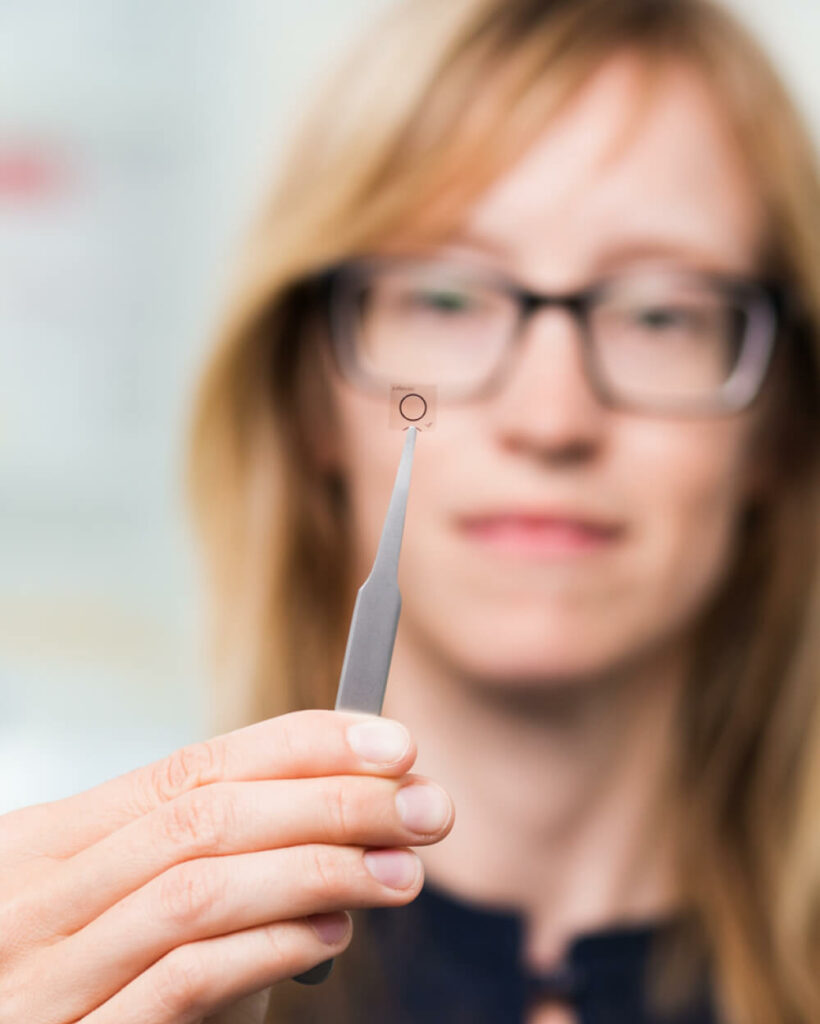

NPS is an optical, versatile technology that detects hydrogen also in the absence of oxygen. Our sensors have palladium alloy nanostructure transducers. In the presence of hydrogen, the optical signature of the nanostructures changes, generating the sensor signal. The sensor signal is reversible and corresponds to the partial pressure of hydrogen in the sensor chip environment.

Specific

Fast

Optical

Low oxygen environments

Flexible

The history of plasmonic H2 sensors – Christoph Langhammer

Watch one of the founders Christoph Langhammer present the history of his work and his experience of measuring hydrogen with our NPS technology

Visit our collection of publications to learn more about how Insplorion’s technology is used.

See publications